Laptop numerical Handle (CNC) procedures are already the foundation stone for modern industries, creating parts in an automated manner at unimaginable production speeds. CNC precision machining has taken it even even more, adding accuracy and simplifying the manufacturing course of action.

It has grown to be the ought to-have technology for complex CNC machining duties that will have to work in tandem. When perfection is required at a microscopic degree, just about every millimeter issues. The sole way to accomplish this perfection is through precision machining.

Kevin Wolf, a former senior Commerce Section official who at the time headed the company that implements U.S. export controls, stated shipments discovered with the Publish probably violated prohibitions Taiwan plus the West imposed final January on the sale of technology to Russia, in reaction to the Ukraine war. He claimed the shipments must “absolutely” be an enforcement priority for authorities in Taiwan.

Ahead of setting up a skyscraper or developing complex, a scaled-down product on the complex is manufactured. CNC machining assists in accomplishing this undertaking.

Unilateral Tolerances: In such a tolerance, variation in Proportions is permitted in just one route. The tolerance Restrict can both be higher than or below the supposed size.

The clinical industry works by using CNC machines to generate a variety of products, together with surgical devices, implants, and prosthetics. These parts ought to meet exacting standards for biocompatibility and precision.

If you want reliable precision machining companies, get in contact with 3ERP, and you will get a quotation inside 24 hrs.

That November, Bredikhin’s business invited a project manager at a drone factory then getting in-built the Tatarstan area, five hundred miles east of Moscow, to go to machine tool production traces in Taiwan.

In any presented sector, the level of equipment that utilizes CNC systems or CNC-designed parts is so vast that it is extremely hard to record them all on this page.

The automotive industry consistently enjoys the takes advantage of of CNC milling machine for both equally prototyping and production.

CNC Milling CNC milling is to chop read more good plastic and metal product into closing precision parts working with unique axis milling processes. Milling may be also known as a wonderful strategy for making tooling for die casting and injection molding. Know a lot more...

A graphical design is essential to build any portion. This can be done with using Pc-Aided Style and design (CAD) software program. The CAD method enables the designer to develop second and 3D designs of any element for manufacture.

Precision grinders are on the list of last manufacturing procedures just after machining parts/components. In precision grinding, abrasive grinders (or grinding wheels) develop a wonderfully flat area with a really smooth finish within the machined parts.

Though the usage of CNC for semiconductors is talked about higher than in applications of electronics and smartphones, the particular use of CNC systems during the industry is way wider.

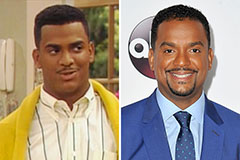

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Batista Then & Now!

Batista Then & Now!